Quality Assurance

The final product, after undergoing the machining stages, is rigorously tested to ensure it is defect-free. This quality assurance process is essential for maintaining the high standards we set for our castings.

The strict testing methods we use, combined with effective quality improvement techniques, have allowed us to manufacture and deliver products of excellent quality. Commitment to quality is at the core of our operations.

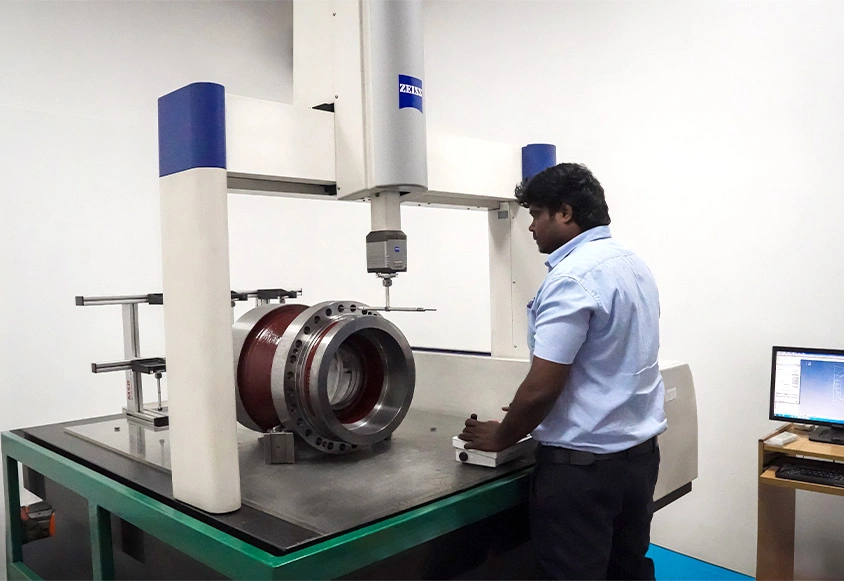

To measure the physical geometrical characteristics of the castings, we use advanced measurement tools and techniques. These tests ensure that each and every product meets the required specifications and tolerances, further strengthening our dedication to excellence in manufacturing.

Co Ordinate Measuring Machine (Cmm)

- Make : CARL ZEISS (Germany)

- Size : X1200mm, Y1600mm and Z600mm

- Accuracy : 0.001 milli microns

Trimos - vectra Touch

- Make : TRIMOS

- Range : 0 - 600mm

- Accuracy : 0.001 milli microns