Quality

At Veejei Automation, we are committed to using the best methods for the continuous improvement of quality. Our goal is manufacturing high-quality iron castings ensuring that every product meets the strict standards.

All and every activity, from the tools we use to the workforce, is designed with quality assurance in mind. With this kind of approach, our focus on quality assurance is sure to make sure that every step of the manufacturing process will eventually add up to giving the final product a quality performance.

We continually upgrade our quality techniques in line with the latest industry trends. This adaptability has enabled us to stay ahead in the competitive casting industry as we continually refine our processes to meet advancing customer demands.

With every innovation and quality, we ensure that our clients receive superior solutions that go beyond their expectations, which further solidifies our reputation as a leader in the field.

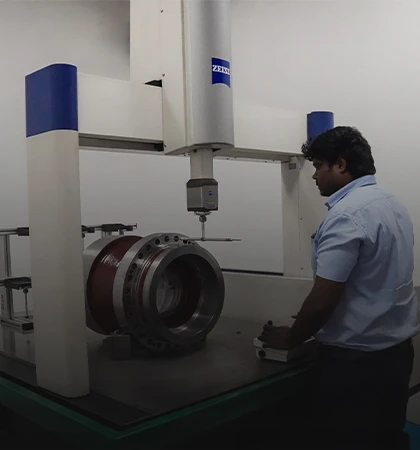

Dimensional Inspection

- All sample castings and random bulk castings are checked for the dimension standard required by the customer.

- Any dimensional variations are immediately reported to the pattern shop to make the necessary corrections.

- Dimensional inspection plays an important role in casting development to maintain the accuracy of the final product.